We use cookies to provide you with better user experience. Cookies settings can be controlled and configured in your web browser at any time.

By using the site you agree to us using cookies and also read privacy policy. To continue viewing and using the website click on “Continue”.

China Feicheng Yutian Chemical-Hydroxy Ethyl Cellulose Manufacturer

-

Self-owned Factory

5,000㎡

-

Global Customers

500+

-

Professional manufacturer

15 years

2022-11-03

News

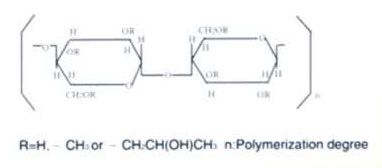

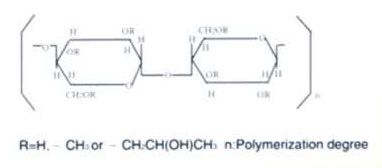

chemical name: hydroxypropyl methyl cellulose (HPMC)

technical requirements:

physical and chemical properties:

technical requirements:

Quality standard

|

project |

I |

II |

III |

|

methoxy |

28-30% |

27-30% |

19-24% |

|

hydroxypropyl |

7-12% |

4-7.5% |

4-12% |

|

Gel temperature |

58-64 |

62-68 |

70-90 |

|

Dry reduction |

≤5% |

||

|

ash |

≤1% |

||

|

PH: 1% solution at 25 ° C |

4-8 |

||

physical and chemical properties:

1. Appearance: white or white powder.

2. Granularity; The pass rate of 100 mesh is more than 98.5%; The pass rate of 80 mesh is more than 100%.

3, carbonization temperature: 280-300℃

4, visual density: 0.25-0.70/cm3(usually about 0.5g/cm3), specific gravity 1.26-1.31.

5, color temperature: 190-200℃

6, surface tension: 2% aqueous solution of 42-56dyn/cm.

7, soluble in water and some solvents, such as appropriate proportion of ethanol/water, propanol/water, trichloroethane, etc. Aqueous solutions are surface active. High transparency, stable performance, different specifications of the product gel temperature is different, solubility changes with viscosity, the lower the viscosity, the greater the solubility, different specifications of HPMC performance has some differences, HPMC in water solubility is not affected by PH value.

8, HPMC with the decrease of methoxy content, gel point increased, water solubility decreased, surface activity also decreased.

9, HPMC also has the thickening ability, salt resistance low ash powder, PH stability, water retention, dimensional stability, excellent film formation, and a wide range of enzyme resistance, dispersion and adhesion characteristics.

The main use:

This PRODUCT IS INDUSTRIAL GRADE HPMC, mainly used for the production of polyvinyl chloride dispersant, suspension polymerization PVC preparation of the main additives. In addition, in other petrochemical, coatings, building materials, paint removal agent, agricultural chemicals, printing ink, textile printing and dyeing, ceramics, paper, cosmetics and other products as thickening agent, stabilizer, emulsifier, vehicle, water retaining agent, film forming agent. The application OF synthetic resin can make the products with regular particles, loose, appropriate specific gravity, excellent processing performance and other characteristics, so as to basically replace gelatin and polyvinyl alcohol as dispersants. In addition, in the construction process of the construction industry, mainly used for building walls, stucco, caulking and other mechanized construction; Especially in the decorative construction, used as paste ceramic tile, marble, plastic decoration, paste strength is high, but also can reduce the amount of cement. Used in coating industry as thickening agent, can make the layer bright and delicate, do not take off powder, improve leveling performance, etc.

Dissolution method:

1. Take the required amount of hot water and heat it to 85℃ or above in the container. Add this product gradually under slow stirring.

2, or heat 1/3 or 2/3 of the hot water to 85-- above, add cellulose, get the hot water slurry, then add the remaining amount of cold water, keep stirring, cooling the resulting mixture is ready.

Six. Precautions for packaging, Storage and Transportation:

Packed in cardboard barrel lined with polyethylene film, net weight of each barrel: 25kg. Protected from sun, rain and moisture during storage and transportation.